FLOOR UNDERLAYS

no.0056

ZAPRAWA ZSF-015 - medium layer self-levelling screed for manual or machine application of levelling and smoothing floor bases, layer thickness from 5 mm to 35 mm. PACKAGING: 25 kg, bag APPLICATION: Indoors

ZAPRAWA ZSF-015 is a self-levelling compound containing micro-reinforcement, designed for levelling and smoothing floor bases inside new and modernised premises. It can be used on various types of cement and concrete substrates. It is recommended in the construction industry as a self-levelling compound with a layer thickness of 5 mm to 35 mm, suitable for residential buildings and general use. - Manual or machine application of the levelling and smoothing layer, - When mixed with water, it forms a mass that is very easy to spread, - Minimum layer thickness 5 mm, - Maximum layer thickness 35 mm, - Wear-resistant screed, - Can be walked on after 6 to 12 hours, - Contains micro-reinforcement, - Used in underfloor heating system, - Possibility of laying further finishing layers after approximately 7 days after pouring, PROPERTIES: ZAPRAWA ZSF-015 is a self-levelling levelling and smoothing compound consisting of dry special cement, carefully selected sand of appropriate grain size, minerals and polymer modifying substances. It is designed for application under various types of floor coverings such as PVC, carpet, ceramic tiles, terracotta, stone, panels, parquet and heated floors. IMPORTANT INFORMATION: - Consumption: 1.5 kg/m2 at 1 mm layer thickness, - Application temperature: +5°C to +28°C, - Mixing ratio: 5 L water per 25 kg mortar, - Foot traffic after: 6 to 12 hours, - Compressive strength: HIGH, - Shelf life: 6 months, - Application method: manual / spray application, - Consumption time: 20 minutes, TOOLS: Drill with mixer, trowel or steel trowel. Clean tools with clean water, immediately after use. MIX PROPORTIONS: Pour the dry mixture (25 kg bag) into 5.0 litres of clean water and mix using a slow speed drill with a mixer until a homogeneous mixture without lumps is obtained. After waiting 3 to 5 minutes, stir the mortar again. Use the mortar so prepared within 20 minutes. Mixing can be carried out with a machine unit with a two-stage mixing system, the remaining stages of the work are carried out as for manual pouring. NOTE: Increasing the amount of water added will reduce the strength.

Remove all loose dirt to prepare the substrate.

Remove loose dirt, paint and gypsum residues mechanically.

All cracks in the substrate should be repaired with repair mortars.

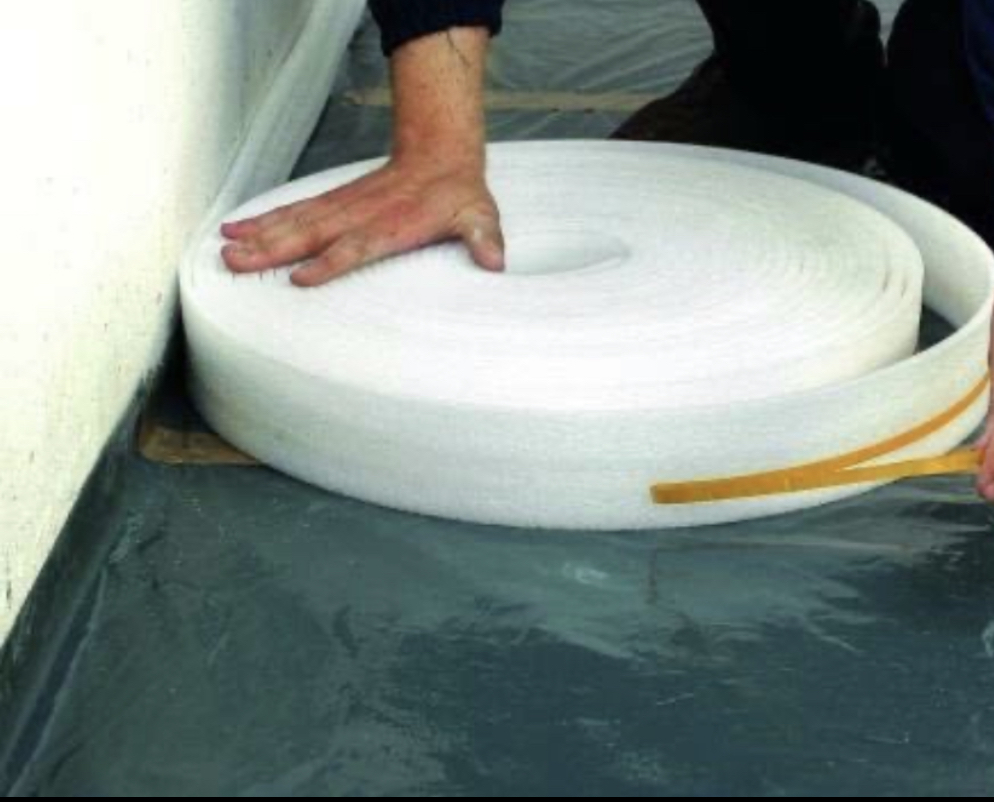

Separate the screed from the walls with special strips or strips of polystyrene.

Prime the substrate with a primer before pouring the mortar.

Pour the self-levelling mortar onto the substrate in a layer between 5 mm and 35 mm thick.

SUBSTRATE PREPARATION: The substrate must be firm, rough and dry, free from dust, oil and grease. Remove loose parts, dirt, paint and plaster residues mechanically. The screed should then be separated from the walls and other structural elements using special tapes or polystyrene strips, preferably 10 mm thick. Repair any gaps and cracks in the substrate using RAPID CONCRETE RC-20 or RAPID CONCRETE RC-30 repair mortars. The substrate should be carefully primed with AKRYL GRUNT STRONGER or HYDRO GRUNT primer before pouring the mortar. EXECUTION: Pour the prepared mortar onto the substrate with a layer from 5 mm to 35 mm thick, vent the poured layer with a spiked roller. Protect against too rapid drying, sunlight, rapid temperature change, low air humidity and draughts. Can be walked on after 6 to 12 hours depending on the type of substrate and the thickness of the mortar layer. Ceramic cladding can be laid after 3 or 7 days depending on air humidity, substrate and thickness of layer laid. Substrate temperature during application from +5°C to +28°C. FURTHER WORK POSSIBLE: The next stage of work depends on the thickness of the primer and the type of covering material. - Ceramic tiles after 24 hours, - Other materials after approximately 7 days, RECOMMENDATIONS: The instructions define the scope of application of the product and the recommended method of carrying out the work, but cannot replace the professional preparation of the work contractor. The manufacturer guarantees the quality of the product, but has no influence on the conditions and method of use. NOTE: The mortar contains cement. Protect eyes and skin. In case of eye blockage, flush with plenty of water. STORAGE AND TRANSPORT: Transport and store mortar in tightly closed bags, in dry conditions, preferably on pallets. Protect from moisture. SHELF LIFE: 6 months from the production date on the packaging. PACKAGING: 25kg bags PALLET: 25kg x 48 bags = 1200kg.

RECOMMENDED

RAPID CONCRETE RC-20 Coarse-grained mortar for repairing and strengthening damaged concrete.

RAPID CONCRETE RC-30 Fine-grained mortar for repairing damaged concrete surfaces.

ZAPRAWA ZW-013 Leveling mortar filling cavities in the substrate.

AKRYL GRUNT STRONGER Primer concentrate for highly absorbent substrates.

AKRYL GRUNT GRUNTEX Universal emulsion priming for highly absorbent substrates.

DO YOU HAVE QUESTIONS WRITE TO US WE ARE HERE FOR YOU

CONTACT

Tel: +251 969 911 100 Tel: +251 911 209 922 E-maim: arsanit4u@gmail.com