THERMA+ TW adhesive mortar is used to create a reinforcing layer, it can also be used for filling and filling small defects. The mortar has very good adhesion to load-bearing, compact, dry and clean surfaces free from oil, dirt, organic substances and all substances that reduce adhesion to the substrate. Walls can be made of masonry elements such as bricks, blocks, stone, etc. or of concrete poured on site or in the form of prefabricated panels.

• High adhesion to substrates,

• Resistant to scratches and cracks,

• Resistant to weather conditions,

• Reinforced with microfibers,

• Reinforced structure,

• Elastic,

PROPERTIES:

THERMA+ TW adhesive mortar is a dry mixture of high-quality cement, mineral fillers and polymers. THERMA+ TW mortar can be used both outside and inside the building.

IMPORTANT INFORMATION:

- Mixing proportions: 5.5 L of water for 25 kg of mortar,

- Application temperature: +5°C to +28°C,

- Shelf life: 12 months,

- Consumption: approximately 4.0 kg/m2,

- Grey colour,

MIXTURE PROPORTIONS:

Pour the dry adhesive mortar mixture into approximately 5.5 L of clean water and mix thoroughly with a low-speed mixer until a homogeneous mixture is obtained. The adhesive is ready for use after 5 minutes and re-mixing.

The adhesive mortar should be used within 2 hours.

SUBSTRATE PREPARATION:

Substrates with high water absorption should be primed with AKRYL GRUNT STRONGER and left to dry for at least 2 hours. Non-absorbent substrates or those contaminated with the remains of substances that reduce adhesion or biocorrosion should be thoroughly cleaned with a brush or using a pressure washer. Additionally, we recommend cleaning with water mixed with ANTIGLO.

EXECUTION:

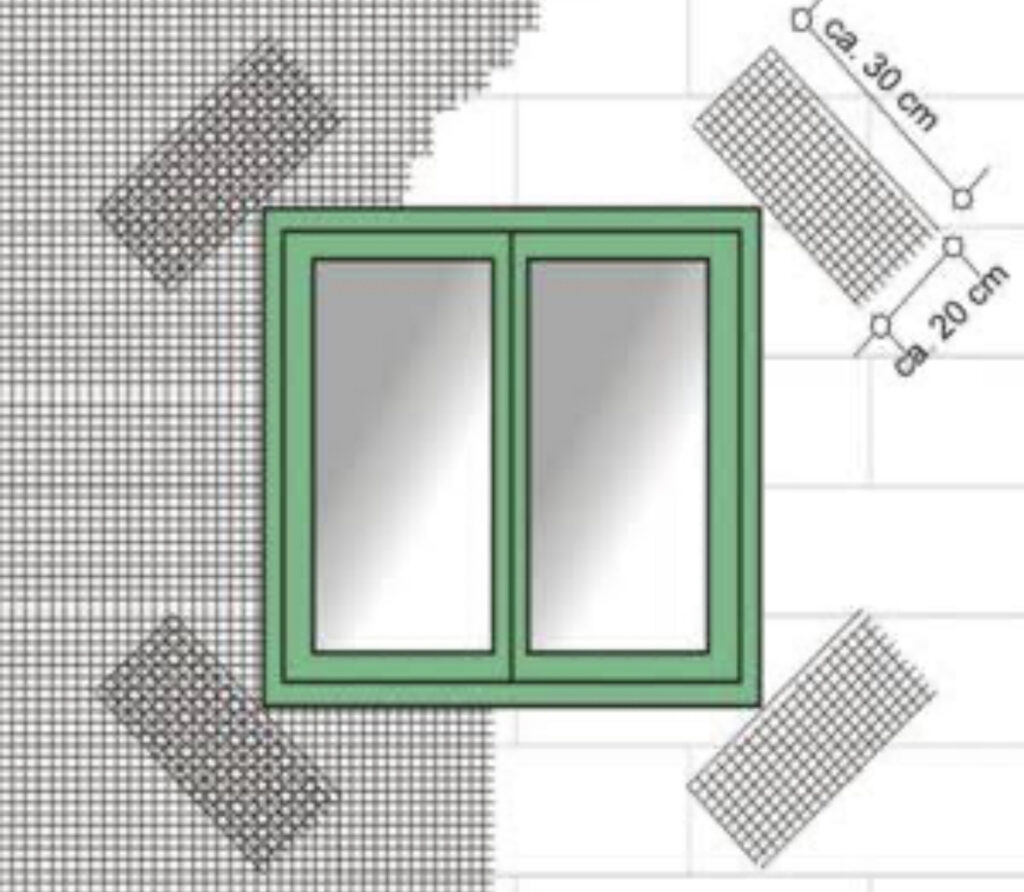

Apply the glue in an amount that will enable the creation of a reinforced layer with a target thickness of 2.5 to 4 mm, then embed the mesh and level the surface. This operation can also be performed in two steps. Apply the glue in vertical strips starting from the top of the wall, the width of the reinforcing mesh. Then immediately embed the reinforcing mesh by pressing it into the glue with a trowel. In the next stage, apply a leveling layer to completely cover the mesh. Approximately 10 cm of mesh overlap should be used in the places where it is joined.