LANAMIK LW adhesive mortar is used for gluing mineral wool boards on typical mineral substrates such as bricks, traditional cement or cement-lime plasters, concrete or aerated concrete. The adhesive mortar can also be used for filling and filling small holes.

- Good adhesion to the ground,

- High durability,

- Easy to use,

- Waterproof,

- Economical to use,

- Environmentally friendly,

IMPORTANT INFORMATION:

- Consumption: approximately 4 kg/m2,

- Mixing proportions: 5.5L – 6.0L of water per 25 kg of mortar,

- Application temperature: +5°C to +28°C,

- Shelf life: 12 months,

PROPERTIES:

LANAMIK LW adhesive mortar is a dry mixture of high-quality cement, minerals and polymers, thanks to which it has high vapor permeability and high efficiency, it is easy and convenient to apply to walls, making it perfect for gluing mineral wool boards. LANAMIK LW adhesive mortar can be used both outside and inside the building.

MIXTURE PROPORTIONS:

Pour the dry adhesive mortar mixture into approximately 5.5 Liters - 6.0 Liters of water and mix thoroughly manually or mechanically until a homogeneous mixture is obtained. The adhesive is ready for use after 5 minutes and re-mixing. LANAMIK LW adhesive mortar should be used within 2 hours.

EXECUTION:

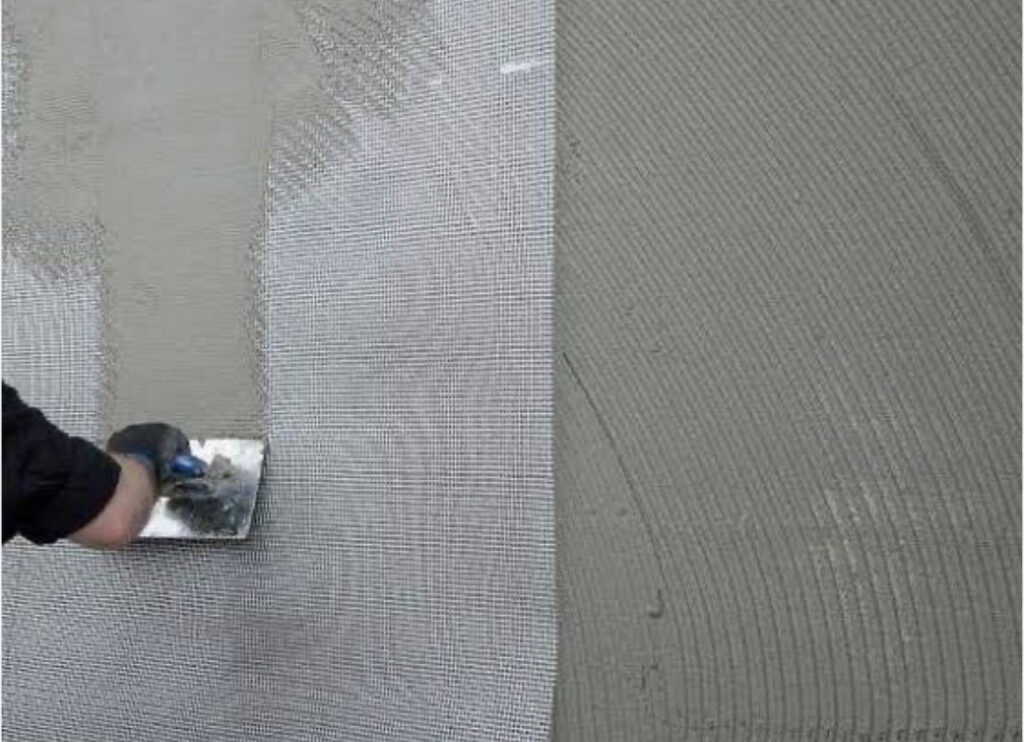

Work should be carried out at temperatures from +5°C to +28°C. The substrate on which LANAMIK LW adhesive mortar is used should be dry, clean, and free from grease, paint residues and other paint coatings. Highly absorbent substrates should be primed with a priming emulsion. In case of gluing to difficult or unstable substrates, an adhesion test should be performed. The boards should be attached using connectors and LANAMIK LW adhesive mortar . In order to glue mineral wool boards, the surface of the board should be smoothed with a thin layer of mortar and after it has set, in the case of even and smooth surfaces, apply the mortar to the entire surface of the board using an 8-12 mm notched trowel so that after gluing it creates a layer 2 mm thick. -7mm. On uneven surfaces, after initial setting of the mortar layer, stick the board using the standard spot method. It involves applying mortar with a trowel around the perimeter of the slab, along its edges, in a strip about 3-5 cm wide. Additionally, 3 to 6 patches of mortar should be placed in the center of the board so that the mortar covers at least 40% of the board's surface in total, and after pressing it to the wall, at least 60%.