REPAIR SYSTEM AND CONCRETE RENOVATION

Renovation and repair of various types of concrete and reinforced concrete structures is an important process that extends the durability of the structure. As a result of long-term use and the action of harmful external factors and loads of various origins, concrete surfaces may be damaged. The damage affects concrete and reinforced concrete structures and poses a threat to the safety and solidity of buildings. The damage affects many buildings and can occur in any structure.

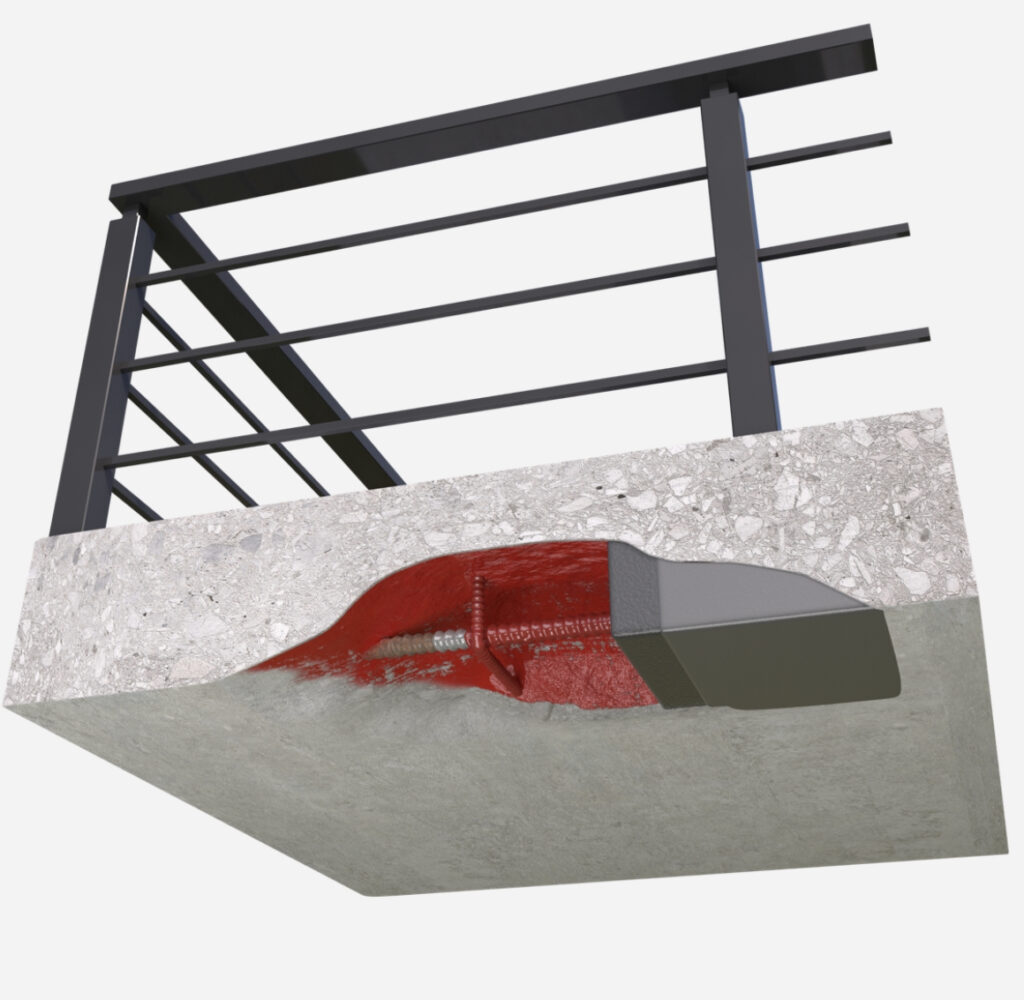

Necessary concrete repair work should be undertaken immediately after noticing the damage - verification of the problem is necessary so that effective repair work can be undertaken and appropriate materials that we offer can be used. The products we offer are intended for comprehensive repair of various types of structures such as: walls, balconies, stairs, ceilings, brackets, columns, structural girders, etc.

CEMENT MORTAR FOR REPAIR DAMAGED CONCRETE

no.0041

RAPID CONCRETE RC-10 - bonding mortar designed to create a contact layer and anti-corrosion protection, enabling the repair of concrete and reinforced concrete damaged by mechanical or corrosive factors. Suitable for repairing elements such as: floors, stairs, balconies, terraces, brackets, columns, lintels, etc.

no.0042

RAPID CONCRETE RC-20 - coarse-grained repair cement mortar 10-60 mm intended for repairing concrete and reinforced concrete damaged by mechanical or corrosive factors. Suitable for repairing elements such as: floors, stairs, balconies, terraces, brackets, columns, lintels, etc.

no.0043

RAPID CONCRETE RC-30 - fine-grained repair cement mortar intended for concrete cosmetics, filling and leveling the substrate in order to improve the quality, close the pores and smooth the substrate.

Depending on the location of the damage, the surface should be reduced to a solid, load-bearing and intact layer, and if necessary, the reinforcement should be cleaned of rust. The resulting gaps should be filled with repair cement mortar. The appropriate type of mortar should be selected - the choice must take into account the location of the repair and the purpose of the repaired surface. Only then can you be sure that the concrete will withstand the loads it will be subjected to and that it will not require additional repairs in the future. Before we start repairing and filling damaged concrete or reinforced concrete with repair cement mortar, we should first prepare the substrate, which must be strong, clean, degreased, without puddles, water stagnation, and loose, unbound particles. The substrate should be cleaned mechanically, preferably with pressurized water or abrasive methods. Before applying the mortar, the concrete substrate should be moistened with water and roughened; there should be no water stagnation and it should be matt and damp. For old, weathered substrates, a bonding layer of RAPID CONCRETE RC-10 or HYDROGRUNT concentrated primer should be applied to provide a bonding layer for the repair cement mortar. RECOMMENDATIONS: The instructions define the scope of use of the product and the recommended method of performing the work, but cannot replace the professional preparation of the contractor. The manufacturer guarantees the quality of the product, but has no influence on the conditions and method of its use. STORAGE: Store in a dry place in closed and undamaged packaging. Protect from moisture. SHELF PERIOD: The shelf life of the product is 12 months from the production date indicated on the packaging.

DO YOU HAVE QUESTIONS WRITE TO US WE ARE HERE FOR YOU

CONTAKT

Tel: +251 969 911 100 Tel: +251 911 209 922 E-maim: arsanit4u@gmail.com